PRESTO W55 Process system

Fast temperature control for larger applications

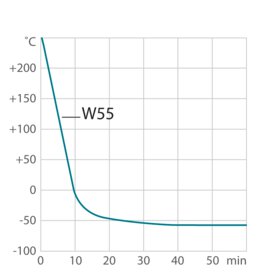

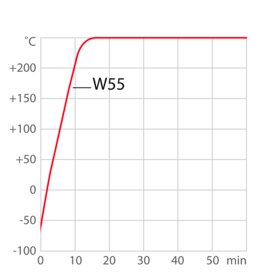

The powerful W55 regulates temperatures with high precision and convinces with faster cool-down and heat-up times. It is ideal for use in large external applications such as reactor temperature control, material stress testing or temperature simulation.

The highly dynamic temperature control systems PRESTO are designed for high-precision temperature control for a wide range of applications such as reactor vessels or material stress tests. Moreover, by using efficient components, the process systems can compensate exothermic and endothermic reactions exceptionally fast. Permanent internal monitoring and self-lubricating pumps ensure a long life-time. In addition, numerous interfaces offer many remote control possibilities across networks or for integration into higher-level control systems.

Performance data depends on the mains voltage in the country of use. Please select:

| Order number including voltage version | see refrigerant variants |

|---|---|

| Working temperature range | -55 ... +250 °C |

| Temperature stability | ±0.05 ... ±0.1 °C |

| Heating capacity | 15 kW |

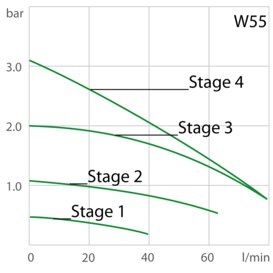

| Pump capacity flow pressure | 0 ... 80 l/min |

| Pump capacity pressure | 0.1 ... 3 bar |

|

Total dimensions

(W × L × H) |

61 x 84.5 x 125 cm |

Product Features

- Temperature stability ±0.05 °C ... ±0.1 °C

- Analog connections, RS485, Profibus DP (accessory)

- Second external Pt100 sensor connection (accessory)

- Built-in 5.7’’ industrial color touchscreen

- Alarm output

- External Pt100 sensor connection

- Cooling capacity up to 15 kW

- Heating capacity up to 15 kW

- Pump pressure up to 3 bar, max. flow rate 80 l/min

Technical data for PRESTO W55

|

Total dimensions (W × L × H) |

61 x 84.5 x 125 cm |

|---|---|

| Internal usable expansion volume | 7.5 l |

| Minimal process volume | 11.5 l |

| Active heat exchanger volume | 7 l |

| Weight | 288 kg |

| Pump connections | M30x1.5 male |

| Cooling Water Connection | G¾ in |

| Working temperature range | -55 ... +250 °C |

|---|---|

| Temperature stability | ±0.05 ... ±0.1 °C |

| Setting the resolution of the temperature display | 0.01 °C |

| Temperature display resolution | 0.01 °C |

| Ambient temperature | +5 ... +40 °C |

Performance data depends on the mains voltage in the country of use. Please select:

| Heating capacity | 15 kW | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cooling capacity

1 Performance specifications measured in accordance with DIN 12876. Cooling capacities up to 20 °C measured with ethanol; over 20 °C with thermal oil unless otherwise specified. Performance specifications apply at an ambient temperature of 20 °C. Performance values may differ with other bath fluids. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pump capacity flow pressure | 0 ... 80 l/min | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pump capacity pressure | 0.1 ... 3 bar | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Viscosity max. | 50 cSt | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Power consumption | 32 A | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Cooling of compressor | 1-stage Water |

|---|---|

| Cooling water pressure max. | 6 bar |

| Max. heat dissipated by unit into cooling water | 26 kW |

| to provide full cooling capacity according to catalog values | |

| Cooling water temperature range | 10 ... 15 °C |

|---|---|

| Cooling water difference pressure | 1.5 ... 6 bar |

| Cooling water consumption 2 | 8 ... 12 l/min |

|

2 Cooling water consumption may vary outside recommended cooling water properties. |

|

| Cooling water temperature range | 5 ... 35 °C |

|---|---|

| Cooling water difference pressure 3 | 0.5 ... 6 bar |

|

3 At cooling water temperatures of 25 °C and higher, the minimum differential pressure is 1 bar. |

|

| Sound pressure level | 65 dbA |

|---|---|

| Classification according to DIN12876-1 |

Classification III (FL) |

| IP Code according to IEC 60529 |

IP 20 |

| Pump type | Centrifugal Pump |

| Interfaces | Alarm output / Ethernet / Modbus TCP/IP / Profibus optional / REG/EPROG optional / RS232 / RS485 optional / SD memory card / Standby-Input optional / USB |

|---|---|

| External pt100 sensor connection | integrated |

| 2nd external Pt100 sensor connection | accessory |

| Integrated programmer | 8x60 steps |

| Temperature control | ICC |

| Absolute temperature calibration | 3 Point Calibration |

| Temperature display | 5.7" TFT Touchscreen |

| Temperature setting | Touchscreen |

| 9421552.16 | 208-230V/3PPE/60Hz (Without Plug) (R452A) |

|---|---|

| 9421552.07 | 400V/3PNPE/50Hz (Plug 32A CEE) (R452A) |

| 9421552.S1.07 | 400V/3PNPE/50Hz (Plug 32A CEE) (R449A) |

Accessory for PRESTO W55

Downloads for PRESTO W55

We would also be happy to send you our printed catalogs and brochures by post.

Request brochurePRESTO W55 Benefits

Touch display. Perfect operation.

With the touch display, the user always has an overview of all values and functions. The intuitive and multilingual menu structure enables perfect control.

Convenience for several users

Administrator level for customizing instrument settings, user levels with limited permissions for fast and safe defined access, password protection, all levels adjustable

100 % Cooling capacity

‘Active Cooling Control’ for cooling available throughout the entire working temperature range, fast cool-down even at higher temperatures

Intelligent temperature control.

Intelligent cascade control - automatic and self-optimizing adaptation of the PID control parameters with external stability of +/- 0.05 °C.

Related Products

Products with similar properties