Special solutions for temperature simulation in electromobility

Over the coming decade, CO2 limit values will be increasingly tightened in important automotive markets. The fact that both legal requirements and customer preferences vary from country to country means that the new electromobility business unit of the automotive and industrial supplier Schaeffler is working with a variety of different drive solutions. Schaeffler has achieved great market success with double clutch and hybrid modules for hybrid vehicles in which the electrical drive is located between the combustion engine and the transmission. The automotive supplier is reacting to the greater susceptibility that electric drives have to failure when compared to combustion engines by carrying out tests under extreme temperature conditions.

In order to be able to guarantee proper and durable functioning of separating clutches, for example, the components need to be subjected to endurance testing under environmental conditions that are as realistic as possible and also to fluctuating extreme temperatures. At the same time, during the tests there is also temperature measurement, measurement of drag torque at various temperatures and functional measurements.

Schaeffler temperature control requirements:

For the quality test of the separating clutch, Schaeffler requires a test environment that makes precise simulation of ambient temperatures possible. The challenge is to subject the test specimens to ambient temperatures from -40 °C to +120 °C during endurance tests. To avoid long downtime or waiting periods during stipulated changes in temperature, quick temperature change from +30 °C to -30 °C within 1½ hours is needed. This requires a space saving and compact solution that controls the temperature of air within the hood.

The JULABO approach:

An air-cooled PRESTO A85 is used in combination with a heat transfer device. The necessary air circulation is provided by a specially adapted, powerful fan with adjustable rotational speed. This means that the rotational speed can be increased for large test specimens to improve the air flow. Fan and heat transfer device are installed within a stainless steel chamber. The PRESTO is attached to the heat transfer device outside and next to the chamber. Testing is carried out in a temperature range of -40 °C to +140 °C. With a cool-down time from +140 °C to -30 °C in around 50 minutes, the PRESTO enables faster temperature change than was prescribed by Schaeffler.

Preliminary tests by JULABO

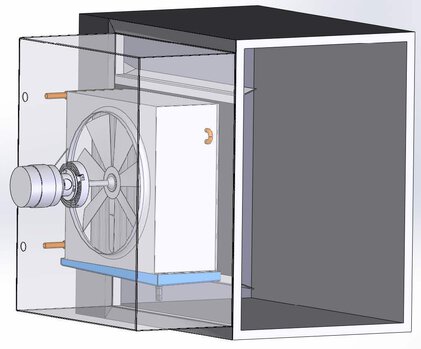

Initial pretests are carried out in a provisional experimental setup at JULABO (Fig. 3). Later the heat transfer device with fan is attached to a stainless steel hood (Fig. 4). The fan sucks the air above and below the heat transfer device out of the front part of the chamber then presses it through the heat transfer device slats that are temperature controlled by the PRESTO A85. This means that cooled or heated air is constantly fed into the chamber with the test specimen.

Challenges for JULABO

Working with extreme temperatures in the negative and positive range creates the following challenges during tests: Electromechanical components of the standard fan are not made for the required extreme temperatures of -40 °C to +140 °C. In order to avoid operating temperature-sensitive parts of the fan inside the hood, the temperature control specialists at JULABO modified the fan to suit the requirements and attached the actual drive motor outside of the chamber (Fig. 5).

Another challenge when working with sub-zero temperatures is the formation of condensation and resulting ice crystals. Due to a small volume within the testing chamber, the air only contains a low percentage of humidity. To avoid fresh air from adding additional humidity, the chamber must be insulated and sealed to be air tight. The low condensation and ice crystal formation due to existing humidity is negligible and has no influence on the temperature control application.

Depending on material, the housing of the heat transfer device can deform due to extreme temperature changes. With increasing temperatures, tested from a room temperature of 20 °C, the housing material slowly expands. With decreasing temperatures the material contracts. While this deformation has no influence on the temperature regulation process, it can have an influence on the position and fit accuracy of connections. Appropriate reinforcement of the housing wall prevents deformation due to changes in temperature.

Heating or cooling of the outer walls due to contact between stainless steel and the heat transfer device is prevented with appropriate construction measures. The use of special materials prevents points of contact between the heat transfer device and stainless steel. This thermal separation as well as the insulation ensures that touching the housing does not cause burns and that strong cooling does not lead to the formation of condensation.

Conclusion:

For engineers at the automotive and industrial supplier, cooperation with a reliable and competent partner was an important precondition for successful implementation of the project.

That’s why various temperature control specialists were contacted to implement the special requirements that Schaeffler had. Only the JULABO consulting team immediately showed a willingness to develop the custom solutions required. In addition to many years of experience and a high level of expertise, this flexibility was crucial for LUK/Schaeffler and the reason that they decided to work with JULABO.

With a development period of only two months, JULABO built a heat transfer device that met all the requirements, and in some cases far exceeded them. In intensive cooperation with Schaeffler, a temperature control solution was created for a universal housing in which the test specimens can be placed in precisely simulated ambient and extreme temperatures during endurance and functional testing (Fig. 7).